what made us start this bulkhead project

Modern design and materials mean we can enhance performance, increasing both strength and rigidity and rectify corrosion problems, whilst retaining the compatibility and integrity of the original.

It was in 2008, that the British economy was in a crisis, which revealed shaky foundations in the banking institutions. Pegasus Parts received a letter from the administrators of a well known classic car manufacture, who believed they owed Pegasus Parts some money, for parts that they had supplied.

They didn’t owe any money, but Paul, the owner of Pegasus Parts looked into the company’s background, to see what it was all about – an interesting story in itself.

It reminded us of a similar long-term project and dream, that we had envisaged…

At the time, everyone was attempting to make a 40-year-old bulkhead perform well beyond its design life.

We discovered that hidden corrosion on poorly repaired bulkheads is often found to be a weakness and sometimes the damage and corrosion incurred is simply too great for them to be successfully repaired. Often the corrosion will break through years later and become visible on what appeared to be a new repaired bulkhead.

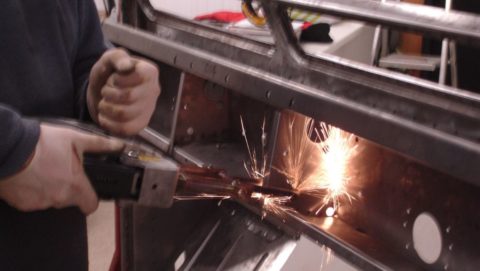

So Pegasus Parts came up with their own solution… to produce new bulkheads with all new metal, initially for Land-Rover Series 2 and 2a models.

After examining many bulkheads of various types and ages, and with our background in manufacturing and production, the bulkhead project was born… It didn’t look too difficult to replicate! Mostly flat panels with very few compound curves. Some complexity around the ventilator lid seals, but nothing that looked too challenging….?