About Us

"it started with a simple idea and our mission remains the same"

To create high quality and original specification bulkheads that we wanted ourselves

Who We Are

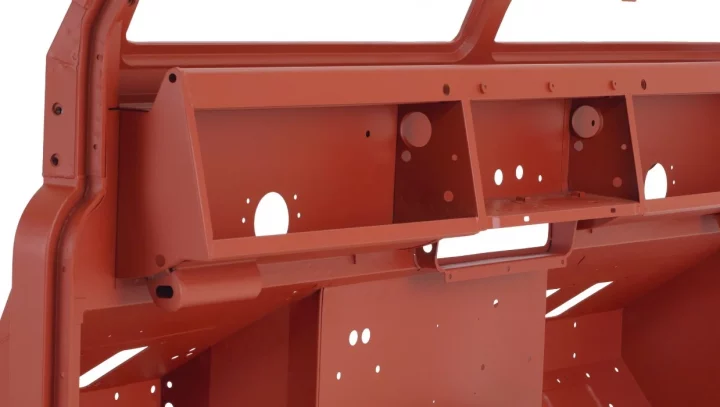

Pegasus Bulkheads is an internationally known manufacturer specialising in bespoke bulkheads for Land-Rover Series models. Founded in 2011, we are a team of passionate Land-Rover enthusiasts who are striving to keep these vehicles looking the same as they left 'The Rover' factory many years ago. All our bulkheads including the parts are made in the United Kingdom. We are proud to support British manufacturing.What We Do

We're in the business of making top quality, high specification, totally accurate bulkheads for classic Land-Rovers from 1948-1990.

How? It starts with our manufacturing principles and management philosophy. All parts have been accurately CAD drawn generating very precise manufacturing drawings. We cut and fold the finished components to then build into sub-assemblies and final assembly, using our 36 reference point jigs, All the spot welds and tig welds replicate the original bulkheads.Why We Do It

That's simple, we exist because we feel these vehicles deserve the highest standards. Our 30 year history of restoring, maintaining and servicing these vehicles meant we have had the privilege to undertake such a re-creation. When Pegasus started this project, everyone was attempting to make a 70-year-old bulkhead perform well beyond its design life, We discovered lots of weaknesses. Hidden corrosion is simply far too great for them to be successfully repaired. So Pegasus came up with a solution. To produce brand new bulkheads with all new metal. Did you know not all bulkheads are made the same? Find out more here.

Our Process

“We would like to think, that if one of the original assembly workers at the Rover factory in Solihull, viewed our bulkheads today, he would find it very difficult to detect any differences to the original”.

Made Stiffer, Stronger and Corrosion Free

Our parts are fabricated with minimal pressing, preserving metal thickness. Using modern design and materials, we have improved performance by strengthening and stiffening weak points by 50% compared to the original bulkhead. This means that not only does the bulkhead maintain its original appearance, but it is also more durable and long-lasting.

Individual Components

We utilize our own designs and patterns to cut and shape the final parts. We have invested in advanced tooling to create a bulkhead that is comparable to Rover's original engineering. Pegasus have extensive experience in sheet metal work and are able to replicate all original pressing details, holes, spire nut locations, and footwell ribs.

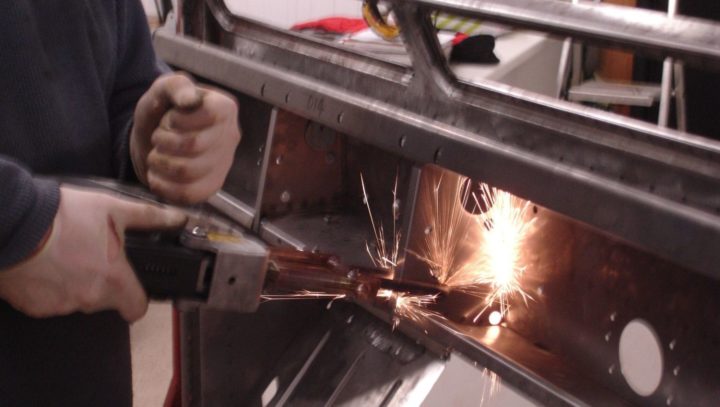

Spot Welded Like The Originals

Pegasus bulkheads are constructed using the same spot welding method as the original bulkheads. The majority of the parts are joined together using spot or TIG welding to create sub-assemblies, which are then assembled into the final assembly. To ensure precise bulkhead geometry, the assembly is constructed on a 36 reference point jigs.

Final stage welded

Pegasus utilize TIG welding on the final assembly for heavy-duty brackets, lap joints, and butt joints. The heavy-duty brackets such as the bonnet hinges, tie rod brackets, and bottom feet are also welded into place using TIG welding to replicate the original oxy-acetylene welding method. We maintain the highest standards in our manufacturing process and have complete control over the quality of each finished bulkhead.

Pegasus finest detailing

Manufactured To Match The Year And Month Your Land-Rover Went Into Production

Not only will your bulkhead fit like the original, last like it’s original, it has all the same features as the original too!

"We would like to think, that if one of the original assembly workers at the Rover factory in Solihull, viewed our bulkheads today, he would find it very difficult to detect any differences to the original".

Series 2/2a – ‘Finger Tip’ press feature and hole for Wiper Motor Socket on the Parcel Shelf Z-Piece.

Series 2/2a – ‘Plunged’ hole for Round Heater Demister tube. This feature carries over to later bulkheads with the ‘Flat’ heater.

Series 2/2a – Rain Channel, with the correct formed hemmed lip.

Series 2/2a/3 – Correct style door pillars with door seal channel extending the full height.

Series 2/2a – Pressed recess for panel Spire nuts on the gear box tunnel.

Series 2/2a – Door Check Tube End Caps. Press formed on our own tooling.

Series 2/2a – Footwells with the original style pressed ribs.

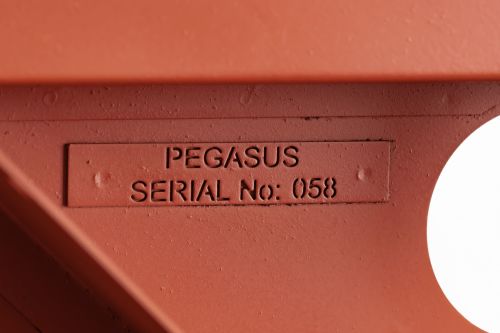

And finally look out for our signature strip, with your bulkhead’s very own laser-cut serial number.

80″ – Correct roll-formed hinges for doors and bonnet.

Rain channel with hemmed front lip.

80″ – Metal spun side lamp pods. The side lamp unit is not supplied with a bulkhead.

80″ – Steering unit reinforcement plate fitted to footwell as required.

80″ – Correct BSF and 2BA threaded fasteners used throughout. Original-style captive nut cages fitted.